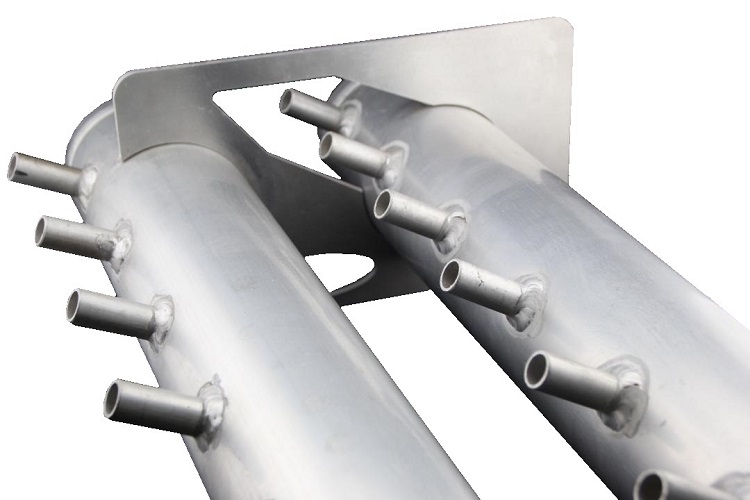

The aluminum extrusions process shapes aluminum by heating it and forcing it with a hydraulic ram through a shaped opening in a die. Extruded material emerges as a long piece with the same profile as the die opening. Once extruded, the hot aluminum profile must be quenched, cooled, straightened and cut.

The extruded products we produce with our certified manufacturers in Vietnam are used in many fields. From automotive parts, medical, machines & devices, electronics, renewable energy, EV charging solutions, solar, food related devices and more.

After the die extrusion process the parts are deburred and if required sawed on the right length. This is only done with mill finished profiles. If any further surface treatment is required we can offer the following secondary finishing:

Secondary surface finishing processes can be:

-Polishing

-Anodizing

-Chromating

-Sand blasting (glass beads, stainless steel beads or aluminum grit)

-Powder coating.